Measuring capacitance with a multimeter might sound like something only professional electronics engineers or electronics hobbyists would do, Βut the truth is, anyone can learn how.

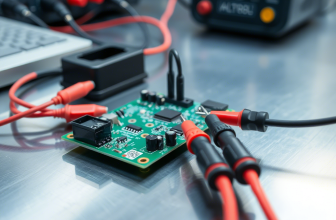

Whether you’re trying to figure out why your power supply isn’t working properly, your audio amplifier has strange noise issues, or your DIY circuit keeps failing, knowing how to measure capacitance with a multimeter can be incredibly useful.

Table of Contents

In this article titled “Multimeter How to Measure Capacitors,” we’ll walk you through everything you need to know in simple, easy-to-understand language. No confusing jargon, no complicated math—just clear instructions for complete beginners.

Capacitors are essential components in almost every electronic device, from smartphones and computers to radios and power tools.

They store electrical energy and release it when needed, helping smooth out voltage fluctuations, filter signals, and stabilize circuits. However, over time, capacitors can degrade, leak, or fail entirely, causing devices to malfunction.

Measuring capacitance helps determine whether a capacitor is still functioning within its expected range or if it needs replacement. This makes it an invaluable skill for troubleshooting electronics, repairing appliances, or even upgrading old equipment.

In this guide, “Multimeter How to Measure Capacitance,” we’ll explain exactly what capacitance is, how it works, and how to use your multimeter to measure it safely and accurately.

You don’t need any prior experience or special tools—just a little patience and a willingness to learn. We’ll also cover safety tips, common mistakes to avoid, and real-life examples of how to test different types of capacitors.

So let’s get started and take the mystery out of measuring capacitance or take a look how to check a capacitor with multimeter!

What Is Capacitance and Why Measure It?

Before diving into the process of measuring capacitance with a multimeter, it’s important to understand what capacitance actually is and why checking it matters. In the simplest terms, capacitance refers to a component’s ability to store electrical charge.

Think of it like a tiny rechargeable battery—it doesn’t generate electricity on its own, but it holds onto electric energy and releases it when needed.

Capacitors, the components that provide capacitance in circuits, are used in a wide variety of applications, such as smoothing out power supply voltages, filtering out unwanted noise, and timing circuits in oscillators and digital systems.

Capacitance is measured in units called farads (F), though most electronic components use much smaller values, typically expressed in microfarads (µF), nanofarads (nF), or picofarads (pF).

For example, a typical electrolytic capacitor found in power supplies might be rated at 100 µF, while a ceramic capacitor used in high-frequency circuits could be as small as 10 pF. The higher the capacitance value, the more electrical charge the component can store.

However, just like batteries, capacitors degrade over time, especially when exposed to heat, moisture, or excessive voltage. When this happens, their ability to hold a charge diminishes, which can lead to erratic circuit behavior or complete failure.

There are many practical reasons to measure capacitance in everyday situations. One of the most common uses is diagnosing faulty capacitors in electronic devices.

If a power supply starts making unusual noises, a motor controller behaves unpredictably, or an audio amplifier produces distorted sound, it could be due to a failing capacitor. By using a multimeter to check its capacitance, you can quickly determine whether it’s performing within its expected range or if it needs replacement.

Another valuable application is verifying component specifications, especially when working with salvaged or older parts. Sometimes, capacitors lose their markings over time, making it hard to tell their exact value. Measuring capacitance allows you to confirm the rating before incorporating them into a new circuit.

Additionally, measuring capacitance helps detect leakage current, which occurs when a capacitor fails to fully insulate its stored charge.

A healthy capacitor should retain its charge without significant leakage, but a damaged one may allow current to slowly escape, reducing efficiency and potentially causing overheating.

Some advanced multimeters include a leakage current test function, but even basic capacitance measurements can give you a good indication of a capacitor’s overall condition.

By understanding capacitance and how to measure it, you gain a powerful tool for diagnosing and fixing electrical problems.

Whether you’re working on home electronics projects, repairing appliances, or simply trying to understand how circuits work, knowing how to measure capacitance gives you valuable insight into the behavior of electrical systems.

Preparing Your Multimeter for Capacitance Measurement

Now that you understand what capacitance is and why it’s important to measure it, it’s time to prepare your multimeter for the task. Unlike measuring voltage or resistance, measuring capacitance requires a slightly different setup, and it’s crucial to do it correctly to ensure accurate readings.

This section of “Multimeter How to Measure Capacitance” will guide you through the necessary steps to ensure you’re ready to proceed safely and effectively.

First, locate the dial or selection knob on your multimeter. This is usually found near the center of the device and allows you to choose what type of measurement you want to take—in this case, capacitance.

On most digital multimeters that support capacitance measurement, there is a dedicated setting marked with a capital “C” or the unit symbol for farads (F). Some models may have multiple capacitance ranges, such as 20nF, 2µF, 200µF, and so on.

If your multimeter does not have an auto-ranging feature, you’ll need to manually select the appropriate range based on what you expect the capacitance to be. If you’re unsure, start with a mid-range setting like 20µF and adjust as needed after taking an initial reading.

Next, insert the test leads into the correct ports on your multimeter. When measuring capacitance, the black lead should always go into the port labeled “COM,” which stands for common. This is your reference point.

The red lead goes into the port labeled “VΩHz” or something similar, which is designated for measuring voltage, resistance, frequency, and sometimes capacitance.

Some multimeters have a separate capacitance input jack labeled specifically for this function, so always refer to your device’s manual to confirm the proper placement of your leads before proceeding.

Using the wrong port can result in inaccurate readings or damage to the multimeter, so always double-check the setup before taking measurements.

One important thing to note when measuring capacitance is that many standard multimeters require you to remove the capacitor from the circuit before testing.

Unlike resistance or voltage measurements, where you can often test components in-circuit, capacitance measurements can be affected by surrounding components, leading to misleading results.

To ensure accuracy, it’s best to desolder or disconnect the capacitor entirely before placing it between the multimeter probes. This ensures that the multimeter is only measuring the capacitance of the specific component you’re interested in.

Once your multimeter is set up, it’s a good idea to perform a quick calibration step, especially if you’re using an older model. Some capacitors may retain residual charge even after being disconnected from power, which can interfere with the measurement.

Before testing, discharge the capacitor by briefly touching both leads together with an insulated tool like a screwdriver.

This prevents any stored electricity from affecting the reading and protects both you and the multimeter from potential damage.

With everything set up correctly, you’re now ready to begin measuring capacitance. In the next section of this guide, “Multimeter How to Measure Capacitance,” we’ll walk you through step-by-step instructions for testing various types of capacitors.

Multimeter deals and offers

Step-by-Step Instructions: How to Measure Capacitance with a Multimeter

Now that your multimeter is properly set up, it’s time to put it into action and measure capacitance in a real-world scenario. This section of “Multimeter How to Measure Capacitance” will walk you through the process in clear, easy-to-follow steps.

Let’s begin with a simple example: checking the capacitance of an electrolytic capacitor. These are commonly found in power supplies, amplifiers, and other electronic circuits where larger capacitance values are required.

Start by identifying the capacitor you want to test. Electrolytic capacitors are usually cylindrical in shape and have polarity markings—one side labeled positive (+) and the other negative (-).

Before taking a measurement, it’s essential to discharge the capacitor completely to avoid damaging the multimeter or getting an inaccurate reading. To do this, use an insulated screwdriver to carefully touch both leads of the capacitor at the same time.

You may see a small spark, which indicates that any stored charge has been released. Once discharged, place the capacitor on a flat surface and position the multimeter probes in your hands.

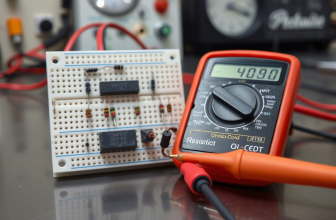

Set your multimeter to the capacitance measurement mode, typically marked with a capital “C” or the unit symbol for farads (F).

If your multimeter offers multiple capacitance ranges, choose one that matches the expected value of the capacitor. For example, if you’re testing a 470 µF capacitor, set the multimeter to the 2000 µF range or the closest available setting.

Now, gently touch the red probe to the positive lead of the capacitor and the black probe to the negative lead. Make sure the probes maintain firm contact with the metal leads of the capacitor. At this point, the multimeter’s display should light up and show a numerical value.

For example, if you’re testing a capacitor labeled as 470 µF, you should expect a reading close to that value.

Depending on the capacitor’s tolerance and age, slight variations are normal—most electrolytic capacitors have a tolerance range of ±20%, meaning a 470 µF capacitor could read anywhere between 376 µF and 564 µF and still be considered within acceptable limits.

If the reading is significantly off, such as showing only a few microfarads or an overload symbol (usually “OL”), the capacitor may be damaged and needs replacement.

Keep in mind that some multimeters require manual range selection, so if your reading shows “OL,” try switching to a higher capacitance range and test again.

Let’s try another example: checking the capacitance of a ceramic capacitor. These are smaller, non-polarized capacitors often used in high-frequency circuits, filters, and timing applications.

Unlike electrolytic capacitors, ceramic capacitors do not have polarity markings, so you can connect the probes in either direction. Begin by discharging the capacitor if necessary (though ceramic capacitors typically store less charge than electrolytic ones).

Set your multimeter to the appropriate capacitance range—since ceramic capacitors are usually rated in nanofarads (nF) or picofarads (pF), choose a low-range setting like 20 nF or 2000 pF depending on the expected value.

Touch the probes to both ends of the capacitor and observe the reading. If the capacitor is labeled as 100 nF, you should expect a reading close to that value. If the reading is significantly lower or shows an open circuit (“OL”), the capacitor may be faulty and needs replacement.

Another common application is testing a film capacitor, often used in motor controls, audio circuits, and industrial equipment. These capacitors are typically encased in plastic and come in a variety of shapes and sizes.

Since they are non-polarized, you can connect the probes in either direction. Follow the same steps as with the ceramic capacitor: discharge if necessary, set the multimeter to the appropriate range, and place the probes on each terminal.

If the reading is within the expected range, the capacitor is functioning properly. If the reading is wildly off or shows no capacitance at all, the capacitor may need to be replaced.

As you practice measuring capacitance in different components, keep in mind that consistency and proper technique are key to obtaining accurate results.

Ensure that the probes make solid contact with the capacitor leads, avoid touching exposed metal parts with your hands, and always double-check your multimeter settings before taking a measurement.

By following these simple guidelines, you’ll quickly become comfortable with the process described in this section of “Multimeter How to Measure Capacitance.”

Understanding and Interpreting Capacitance Readings

Once you’ve taken a capacitance measurement, the next step is understanding what the numbers on your multimeter mean. In this part of “Multimeter How to Measure Capacitance,” we’ll break down how to interpret the readings you see on the display and what they signify about the capacitor’s condition.

While the exact appearance of the display may vary slightly depending on your multimeter model, most digital versions will show a numerical value followed by a unit of measurement—typically farads (F), microfarads (µF), nanofarads (nF), or picofarads (pF).

Let’s start with basic capacitance values. Suppose you measured an electrolytic capacitor labeled as 100 µF and saw a reading of 98 µF. This means the capacitor is functioning within its expected range, accounting for minor manufacturing tolerances.

Most capacitors have a tolerance rating of ±20%, meaning their actual capacitance can vary slightly from the stated value. If a capacitor rated at 470 µF reads 400 µF or 520 µF, it’s still within acceptable limits.

However, if the reading is drastically different—for example, 50 µF instead of 470 µF—it suggests the capacitor is damaged or degraded and needs replacement.

When testing ceramic or film capacitors, the expected values are much smaller, often in the nanofarad (nF) or picofarad (pF) range. For instance, if you tested a ceramic capacitor labeled as 10 nF and got a reading of 9.8 nF, that indicates a healthy, functional component.

However, if the reading jumps to several hundred nanofarads or displays an overload symbol (“OL”), it means the capacitor is either shorted or has incorrect internal insulation. This is particularly useful when troubleshooting timing circuits, oscillators, or filters where precise capacitance values are critical.

One thing you might encounter when interpreting capacitance readings is an “OL” symbol on the display. This stands for “Overload” and appears when the capacitance you’re measuring exceeds the selected range on your multimeter.

For example, if you set your multimeter to 20 µF but try to measure a 100 µF capacitor, the display will show “OL” because the capacitance is too high for that setting. To resolve this, simply adjust the multimeter’s dial to a higher capacitance range and try again.

Some modern multimeters have auto-ranging capabilities, which automatically detect and display the correct capacitance without requiring manual adjustments.

If your multimeter has this feature, you won’t see an overload warning unless the capacitance exceeds the device’s maximum limit, which is typically several thousand microfarads.

It’s also important to note that minor variations in readings are normal and don’t necessarily indicate a problem. Environmental factors, component age, and the quality of your multimeter can all influence the precision of the measurement.

As long as the reading stays within an expected range for the capacitor you’re testing, there’s generally nothing to worry about.

With this knowledge, you’ll be better equipped to assess whether the capacitance levels you’re measuring are within acceptable limits, allowing you to make informed decisions about your electrical equipment.

Common Mistakes and Safety Tips When Measuring Capacitance

While measuring capacitance with a multimeter is generally safe when done correctly, there are some common mistakes that beginners often make. One of the most frequent errors is attempting to measure capacitance in a live circuit.

Unlike voltage measurements, which can be taken while a circuit is powered, capacitance measurements should only be performed on components that are completely disconnected from any power source.

Measuring capacitance in a live circuit can damage the multimeter, give inaccurate readings, or even pose a risk of electric shock. Always make sure the device or component you’re testing is unplugged and fully discharged before taking any capacitance measurements.

Another mistake many newcomers make is failing to remove the capacitor from the circuit before testing it. When a capacitor remains connected to other components, the multimeter may pick up additional interference, leading to misleading readings.

For example, if you try to measure a capacitor while it’s still soldered onto a circuit board, the presence of nearby resistors or diodes can skew the result. To get an accurate measurement, it’s best to desolder or disconnect the capacitor entirely before testing it.

This ensures that the multimeter is only measuring the capacitance of the specific part you’re interested in.

Incorrectly selecting the capacitance range is another issue that can lead to confusion or inaccurate data. Many multimeters offer multiple capacitance settings, such as 200pF, 2nF, 20µF, and so on.

If you set the multimeter to a range that is too low for the component being tested, the display may show an overload symbol (“OL”) instead of the actual capacitance value.

Conversely, if you select a range that is too high, the reading might lack precision—for instance, a 100 µF capacitor measured on a 2000 µF scale may appear as 0.00 µF, making it hard to distinguish between a good and faulty component.

To avoid this, start with a mid-range setting like 20 µF and adjust accordingly based on the initial reading.

Additionally, neglecting to discharge the capacitor before testing can introduce unwanted variables. Even after disconnecting a device from power, capacitors can retain a charge for some time, especially large electrolytic capacitors found in power supplies and amplifiers.

Failing to discharge them before measurement can result in inaccurate readings and potential damage to the multimeter. To safely discharge a capacitor, use an insulated screwdriver to briefly touch both leads together. This allows any stored electricity to dissipate, ensuring a clean and accurate measurement.

Lastly, failing to clean the capacitor’s leads before testing can introduce unwanted resistance or interference. Dirt, oxidation, or corrosion on the surface of the leads can affect the connection between the capacitor and the multimeter probes, leading to false readings.

Before placing the probes on a component, gently wipe the leads with a clean cloth or lightly sand them to remove any debris or tarnish. This ensures a solid connection and improves the accuracy of your capacitance measurements.

By being mindful of these common pitfalls and following basic safety precautions, you can ensure that every capacitance check you perform is both accurate and secure.

Troubleshooting Electrical Problems with Capacitance Measurements

Now that you know how to measure capacitance and interpret the readings, let’s explore how to use this knowledge for troubleshooting common electrical issues.

In this section of “Multimeter How to Measure Capacitance,” we’ll walk through real-world scenarios where measuring capacitance can help identify problems in everyday devices and circuits.

Whether you’re dealing with a malfunctioning power supply, a noisy audio amplifier, or a motor that won’t start, a multimeter can be a powerful diagnostic tool.

Let’s start with a simple example: a desktop computer power supply that intermittently fails to start. Power supplies rely on large electrolytic capacitors to smooth out voltage fluctuations and provide stable power to the system.

Over time, these capacitors can degrade, leading to unstable output voltages and random shutdowns. To test them, first unplug the power supply and open the casing. Discharge each capacitor by briefly touching both leads together with an insulated screwdriver.

Then, set your multimeter to the capacitance measurement mode and test each capacitor individually. If a capacitor labeled as 470 µF reads significantly lower—say, only 200 µF—it means the capacitor has lost its ability to store charge properly and needs replacement.

Replacing these faulty capacitors can often restore normal operation without needing to replace the entire power supply.

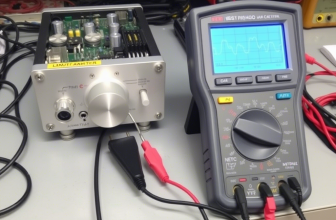

Another common scenario involves a car audio amplifier that produces distorted or crackling sounds. Amplifiers use capacitors to filter out noise and stabilize power delivery to the speakers.

If a capacitor in the power filter circuit fails, it can cause audible distortion or intermittent power loss. To test this, disconnect the amplifier from the power source and discharge any remaining charge in the capacitors.

Use your multimeter to measure the capacitance of the large filter capacitors near the power input. If the measured value is significantly lower than the rated value printed on the capacitor, it indicates degradation and warrants replacement.

Fixing this issue can dramatically improve sound quality and prevent further damage to the amplifier circuitry.

Household appliances can also benefit from capacitance checks. Imagine a washing machine motor that struggles to start or hums without turning. Many single-phase AC motors rely on a start capacitor to provide the initial boost needed for rotation.

If this capacitor fails, the motor may not spin at all or may run inefficiently. To test the start capacitor, disconnect the appliance from power and locate the capacitor near the motor housing.

Discharge it carefully, then set your multimeter to capacitance mode and test the component. A healthy motor start capacitor typically has a rating between 5 µF and 100 µF, depending on the motor size.

If the measured capacitance is far below the rated value or shows an open circuit (“OL”), the capacitor is likely faulty and needs replacement. This simple fix can save you from unnecessary motor replacements and expensive repairs.

By systematically checking capacitance at different points in a circuit, you can isolate the source of the problem and avoid unnecessary replacements.

Whether you’re troubleshooting electronics, automotive systems, or household gadgets, knowing how to measure capacitance gives you a valuable advantage in diagnosing and resolving electrical issues efficiently.

Expanding Your Multimeter Skills: Beyond Basic Capacitance Checks

Now that you’ve mastered the fundamentals of measuring capacitance with a multimeter, you can begin exploring additional ways to use your tool for more advanced diagnostics.

In this final section of “Multimeter How to Measure Capacitance,” we’ll introduce a few practical applications that build upon your newfound skills, helping you get the most out of your multimeter.

While capacitance measurement is an essential starting point, your multimeter can also assist with checking capacitor leakage, testing timing circuits, and even identifying damaged components in complex electronics.

One particularly useful skill is learning how to test for capacitor leakage current. Leakage current refers to the small amount of current that flows through a capacitor even when it’s supposed to block direct current (DC).

While some level of leakage is normal, excessive leakage can cause a capacitor to fail prematurely or affect circuit performance. Although most standard multimeters don’t directly measure leakage current, you can estimate it by measuring the capacitor’s resistance.

Start by charging the capacitor to its rated voltage using a safe power supply, then switch your multimeter to resistance (Ω) mode and measure across the capacitor’s terminals. A healthy capacitor should show very high resistance—typically in the megaohm range.

If the resistance drops significantly over time or reads abnormally low, it indicates excessive leakage, and the capacitor should be replaced.

Testing timing circuits is another valuable application that builds on your capacitance-measurement knowledge. Many electronic circuits, such as LED flashers, pulse generators, and motor controllers, rely on capacitors to control timing intervals.

By measuring the capacitance of timing capacitors and comparing them to their rated values, you can determine whether they are contributing to unexpected behavior in the circuit.

For example, if a blinking LED circuit is flashing too quickly or too slowly, a faulty timing capacitor could be the culprit. Replacing it with a known-good component of the correct capacitance can restore normal operation.

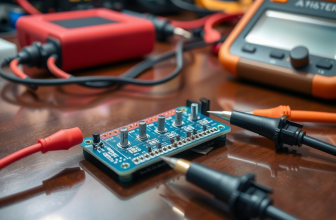

Another practical use of capacitance measurement is identifying damaged components in complex electronics. High-end devices like smartphones, laptops, and gaming consoles contain numerous small capacitors that regulate power delivery and signal integrity.

When these components fail, the device may exhibit symptoms like random reboots, screen flickering, or charging issues. Using a multimeter with fine-tipped probes, you can inspect and measure individual capacitors on a circuit board to identify faulty ones.

This technique is especially useful when repairing water-damaged electronics, as corrosion can degrade capacitor performance over time.

By expanding your capacitance-testing techniques beyond basic checks, you gain a more comprehensive toolkit for diagnosing and repairing electrical problems.

Whether you’re verifying capacitor health, assessing timing circuits, or tracking down hidden faults in electronics, these additional skills enhance your ability to troubleshoot effectively.

With consistent practice and exploration, your multimeter will become an indispensable companion in both everyday fixes and more complex electronic projects.